Written by Owen Peckham & Ben Hicks, University of Bristol

The term ‘Generative Design’ (GD) has exploded in recent years, appearing with increasing frequency in all forms of media – from academic articles, where researchers explore its ability to create lighter, stronger components to TikToks, where bionic-looking systems engage and excite future engineers. In this article we will discuss how and why the technology is being adopted by industry alongside challenges and barriers. To illustrate its applications, we will begin by looking at its use in large-scale architectural projects before moving on to its growing role in product and industrial design.

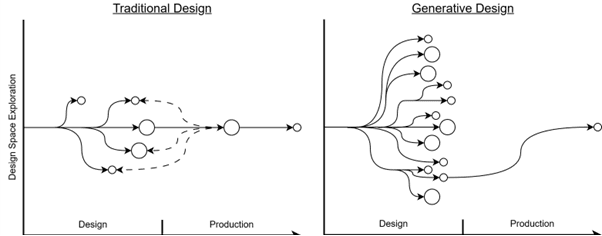

First, what is GD? It is commonly confused with topology optimisation, a term used to describe computational methods that add or remove material from a single structure to achieve some goal (reduced weight, drag etc.). In contrast, GD systems have a broader goal. Instead of optimising a single design they produce many – tens, even hundreds at a time – often without the user having to specify an existing design to modify. GD toolchains can evaluate a range of different materials, loading scenarios and possible manufacturing approaches simultaneously, exploring every combination and mapping a large portion of the feasible design space. These advantages have never been available to designers before. All this, combined with the power of cloud computing, affords a step reduction in design cycle times, allowing more rapid iteration and ultimately better products. This potential is the reason why a growing number of companies are adopting GD toolchains. This growth is highlighted in the examples of real-world GD usage below. The image below is a mapping of how these capabilities shorten time to market by enabling maximum design space exploration very early in the design process. The process not only compresses the concept-to-detailed design phase but radically changes the process from one of down selection and serial concept development to exponential solution generation and evaluation of the solution space – all in a fraction of the time.

Figure 1: Adapted from the figures on slides 9 & 10 in a presentation given by Gilberto Fernandez on behalf of Autodesk University in 2019. The full presentation can be found at https://static.au-uw2-prd.autodesk.com/Class_Handout_MFG322481_Gilberto_Fernandez.pdf (accessed 15th October 2025).

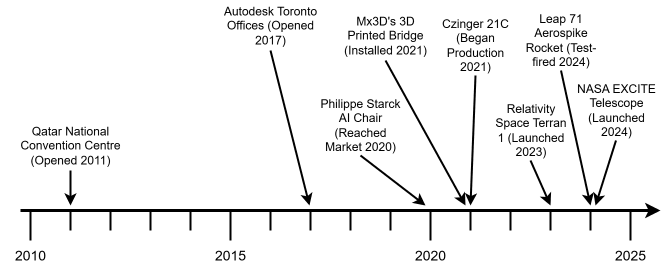

The first example of a GD project that made it beyond the concept stage to construction was the Qatar National Convention Centre, which opened in December 2011. The natural-looking structure that supports the iconic 250m long and 20m high entrance was conceived by architects Arata Isozaki and Mutsuro Sasaki to be both functional and aesthetically reminiscent of the branches of Sidra trees, which are culturally significant in Qatar. The structure was designed with the help of a 3D evolutionary structural optimisation approach, which generates multiple solutions then combines their best attributes to create a diverse set of forms that make efficient use of materials to support the required forces. The architects then chose the most aesthetically pleasing solution. This collaboration enabled Isozaki and Sasaki to best utilise their skill sets in complement with the computer’s. To bear the load once built, the ‘branches’ have an internal octagonal steel core which is then clad using single and double curvature panels to complete the form. Such an approach was only made possible due to the large budget of the project, illustrating a significant barrier for designers considering GD when compared to traditional approaches such as concrete columns. The next example of GD in architecture was not seen until 2017. For this, American CAD vendor Autodesk demonstrated its cutting-edge building design software ‘Dynamo’ by optimising the floor plan of its new Toronto office. The process began by interviewing employees about their needs and preferences, gathering 24 parameters to define eight regions. This information was used to generate thousands of potential layouts that adhered to constraints such as the location of support columns. Designs were then scored according to the multiple objectives (daylight exposure, views, adjacency to other teams, …) before an outcome that balanced all the goals was chosen. The primary drawback of this approach was the up-front cost of gathering the detailed data needed to drive the process, however, as similar projects are conducted with increasing frequency this upfront cost will reduce. These two buildings illustrate how GD can be applied using traditional manufacturing approaches. As we will see, however, many GD projects leverage recent manufacturing advances to unlock design solutions that cannot be realised with traditional manufacturing techniques.

Figure 2: Qatar National Convention Centre front entrance. Image taken from https://www.qncc.qa/ (accessed 15th October 2025).

Still considering civil projects, the trend of combining GD with novel manufacturing is exemplified by the stainless-steel pedestrian bridge installed over a canal in Amsterdam in 2021. The project was a collaboration between Dutch robotics company MX3D, design firm Joris Laarman Lab, and engineering consultancy Arup. Using Autodesk Fusion’s GD tools, the team generated an organic design that was optimized to be as lightweight as possible while withstanding its predicted loads. The project was made possible by its groundbreaking fabrication method: the 12-meter-long bridge was 3D printed in stainless steel using robotic arms over six months. This technique, known as Wire Arc Additive Manufacturing (WAAM), enabled the load-bearing structure to be realized without the limitations and geometric constraints of traditional casting or machining processes. The benefits are clear, combining GD with additive manufacturing enables massive design freedom that minimises the material required whilst meeting the constraints of the location. As a bonus the bridge is heavily loaded with sensors, tracking crowd behaviour and structural health to enable a ‘digital twin’ which both informs maintenance and acts as a research tool for future projects. The trade-off between the advantages and cost presents a major barrier to wider uptake: the WAAM process required to create the complex design is cutting edge, requiring high capital investment and a long production time which limits the usability of the approach to one-off projects.

Figure 3: MX3D’s metal 3D printed bridge in Amsterdam. Image taken from https://mx3d.com/case/mx3d-bridge/ (accessed 15th October 2025).

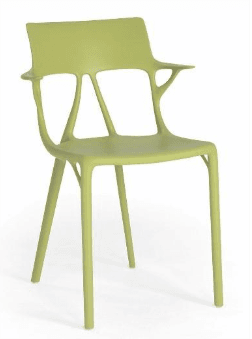

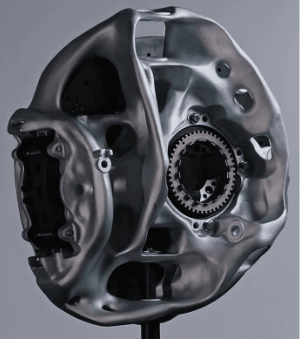

The futuristic aesthetic of GD outcomes is also driving adoption in product design. The first case of a GD product that successfully made it to market is the ‘AI Chair’, which has been on sale with Kartell since 2020. Using Fusion, designer Philippe Starck input the requirement to create a structurally sound chair using the minimum amount of material. An injection moulding manufacturing constraint was also added to ensure that the resulting designs could be mass-produced with traditional tooling, challenging the common belief that GD is only useful in conjunction with 3D printing. The software explored a range of possible outcomes that considered different plastics and loading scenarios. This collaboration also emphasises the importance of the human designer who then selected the final design based on the desired aesthetic. An example of a performance driven consumer product developed with GD is the Czinger 21C hyper car, which began a limited production run of eighty units in 2021. Here GD was used for its structural optimisation capabilities via ‘DAPS’, an in-house software proprietary to Czinger’s parent company, Divergent 3D, that integrates design, fabrication, and assembly into a single toolchain. The lightweighting advantages gained from this approach extends beyond single components, allowing multiple parts in assemblies to be consolidated, e.g. combining eight pieces across the suspension and the brake callipers into a single ‘brake node’ at each wheel. The results of these efforts were apparent in 2021 and 2024, when the 21C broke lap records for production cars at Laguna Seca, The Goodwood Festival of Speed, and Circuit of the Americas. Above and beyond lightweighting, the GD process used in the 21C resulted in components with a bionic, skeletal aesthetic, turning functional parts into industrial art that enables the car to grab headlines. The car’s estimated £1.6 million price tag is a direct consequence of the cutting-edge metal 3D printing approach required to manufacture such high performance structurally optimised components, a cost that currently restricts its revolutionary potential to the exclusive hyper car market.

Figure 4: Left) The Philippe Starck AI Chair. Image taken from https://adsknews.autodesk.com/en/news/generative-design-starck-kartell/ (accessed 15th October 2025). Right) A ‘Brake Node’ from a Czinger 21C. Image taken from a reel posted by Czinger’s official Instagram account at https://www.instagram.com/reel/DAEQJH_vEnl/ (accessed 15th October 2025).

Alongside the success of the Czinger 21C there are several examples of GD projects that have not made it to market. In 2018 General Motors began an explorative study looking at the feasibility of consolidating eight components in the seat bracket of one of their car models into a single GD part with a view to putting this upgrade into production as early as 2023. Alongside ease of assembly the primary motivators for this study were the GD component being 40% lighter and 20% stronger than the original assembly when manufactured from stainless steel using 3D printing. Unfortunately, the requirement to use 3D printing to recreate the complex geometry proved too costly and the project was paused due to the expense and relatively slow speed of 3D printing compared to mass-market automotive production. This project is not alone in highlighting the trade-off between a technologically optimal solution and one that is commercially viable.

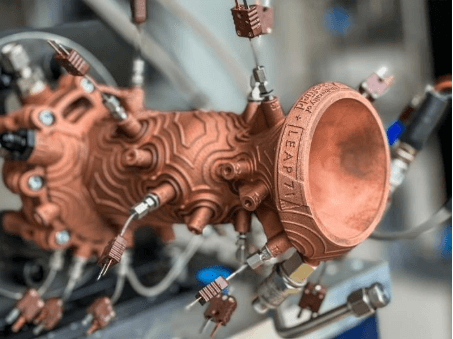

The most recent reported uses of GD are high-value industrial aerospace components, where the technology’s value proposition is perhaps clearest. When the cost to send a single kilogram into orbit can be thousands of pounds, the economic incentives and sustainability goals combine to create a powerful business case for using advanced design and manufacturing, as every gram saved reduces the amount of fuel required for launch. For example, the Relativity Space Terran 1, which launched in 2023, used GD to design large, consolidated structures to drastically reduce part count and complexity. Amongst other uses in this project the GD process resulted in the reduction of over a thousand components down to six in the fuel pump. Similarly, in 2024 NASA launched its EXCITE telescope which included mounting brackets designed by Autodesk’s GD tool to create a structure 30% lighter than its predecessor for the same strength when 3D printed from Aluminium. Meanwhile the Dubai-based startup Leap 71 has demonstrated the reduced design cycle periods offered by GD. Also in 2024, they successfully test-fired a Noyron TKL-5 rocket thruster which was designed by their proprietary computational software from scratch in just two weeks, a task that traditionally takes many months.

Figure 5: Left) EXCITE telescope mounting brackets printed in aluminium. Image taken from https://etd.gsfc.nasa.gov/capabilities/capabilities-listing/generative-design/ (accessed 15th October 2025). Right) Leap 71’s Noyron TKL-5 rocket thruster. Image taken from https://leap71.com/2024/06/18/leap-71-hot-fires-3d-printed-liquid-fuel-rocket-engine-designed-through-noyron-computational-model/ (accessed 15th October 2025).

A second example of a GD component that was intended for mass production is the Airbus ‘bionic partition’ developed in 2016. Here Airbus partnered with Autodesk to create a cabin separator for its A320 passenger aircraft. The primary design driver for using GD in this case was the lightweighting benefits, since the optimised component was 45% (30kg) lighter than the standard partition when 3D printed using aluminium. If scaled up over thousands of aircraft flying millions of miles each, this weight reduction would provide significant fuel savings. Unfortunately, the partition did not make it to market in its original form. Airbus struggled significantly with certification, which is a rigorous and lengthy process for structurally critical commercial aviation components. As a result, the final updated partition that fitted to new A320s was redesigned to use a composite sandwich panel.

The projects summarised above demonstrate that GD is a powerful technology. Despite this, there are not many examples of true GD industrial-scale projects that have successfully reached the consumer. This is primarily due to the generally high cost of producing GD components in high volume production industries. This underscores the growing need to apply GD not just with advanced 3D printing, but also with cost-effective traditional methods like injection moulding, as seen with the AI Chair, to make its benefits more accessible. In contrast, these barriers are less insurmountable in industrial design and architecture where premium one-off designs are commonplace and can command a high price tag. Despite these challenges, the advantages of GD mean it is here to stay, with increasing industrial interest and capabilities including design for manufacture using more traditional techniques such as machining and injection moulding. For engineers, the increasing number of CAD vendors aiming to join Autodesk in the GD space including Dassault Systemes, PTC and nTopology, means a shift in focus both upstream and downstream in the design process, to problem definition and evaluation respectively, away from design synthesis to the aspects of designing that require human creativity and real-world understanding. For companies to fully leverage the technology they will have to adapt their workflows and team structures accordingly. For all of us, the use of GD promises an exciting future. Its primary applications – lightweighting, part consolidation, and performance optimisation – directly align with critical sustainability goals by reducing material consumption and improving energy efficiency throughout a product’s lifecycle.

Figure 6: CAD tools that offer GD modules as of 2025.